New line of Klimaoprema kitchen hoods

2.11.2021

Induction kitchen hoods

Designing ventilation systems for commercial kitchens

Designing ventilation for commercial kitchens is a very complex process that poses a great challenge. In addition to knowing the norms and design guidelines, in conditions of a significantly large number of air exchanges, it is necessary to balance the various variables extremely well to achieve proper air distribution in the room and achieve a comfortable working space.

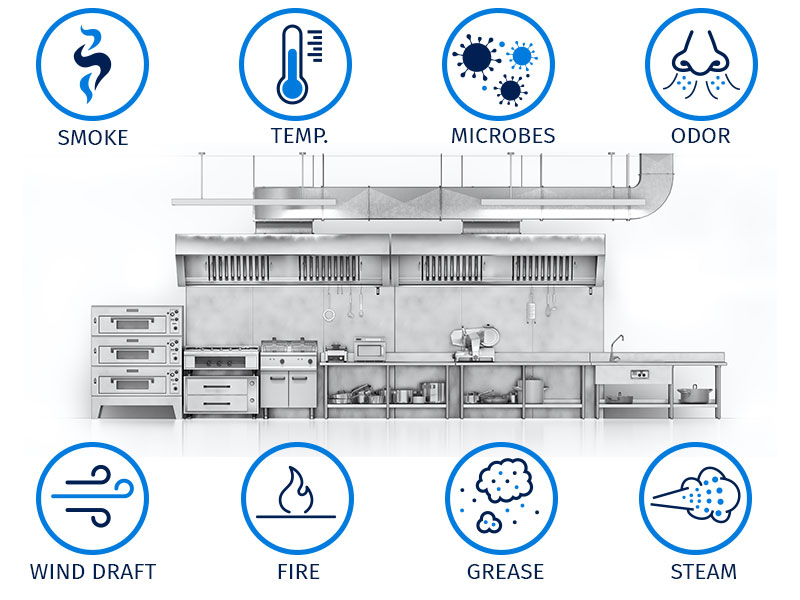

During cooking or dishwashing, large amounts of heat, moisture and grease vapor are generated in the kitchen area. This kind of environment promotes the development of microorganisms in parts of the ventilation system and the kitchen itself. Unpleasant odors, excessive air flow (drafts), grease build-up and the risk of fire are additional problems that, by choosing the right elements of the exhaust ventilation system, can be eliminated, or at least controlled.

Kitchen hood - essential part of commercial kitchens’ ventilation system

A key part of an efficient ventilation system for commercial kitchens are kitchen exhaust hoods which, among other extraction elements, ensure a clean, safe, and comfortable working space. Therefore, it is important to make the right choice of the kitchen hood according to the type and purpose of the kitchen, the capacity of cooking equipment, the required amount of air exhausted and the size and position of the blocks of kitchen appliances (thermoblocks). The sizing of kitchen hoods, the materials they are made from, the minimum installation height, the volume of the exhaust unit, the air flow rate, the type of filter, lighting and the size and position of the connections are prescribed in the European standard EN 16282.

KH line of kitchen hoods

Klimaoprema has developed a new line of kitchen hoods in accordance with the EN 16282 standard:

• Type KHE are conventional kitchen hoods that only have an exhaust unit without the possibility of supplying fresh air. According to the installation position, the hoods can be wall-mounted or ceiling-mounted, and according to the shape they can be rectangular or, for spaces with lower ceilings, tapered.

• Type KHI are induction kitchen hoods which, in addition to the exhaust unit, also have a supply air unit for the preparation of the induction air jet and the possible supply of fresh air. They can also be wall-mounted or ceiling-mounted, but due to their supply unit they can only be rectangular in shape.

• Type KHC are condensate hoods designed to exhaust steam above dishwashers.

Induction kitchen hood

The induction kitchen hood is especially interesting due to the application of numerous solutions that contribute to very high efficiency. The most important features of this model of kitchen hoods are:

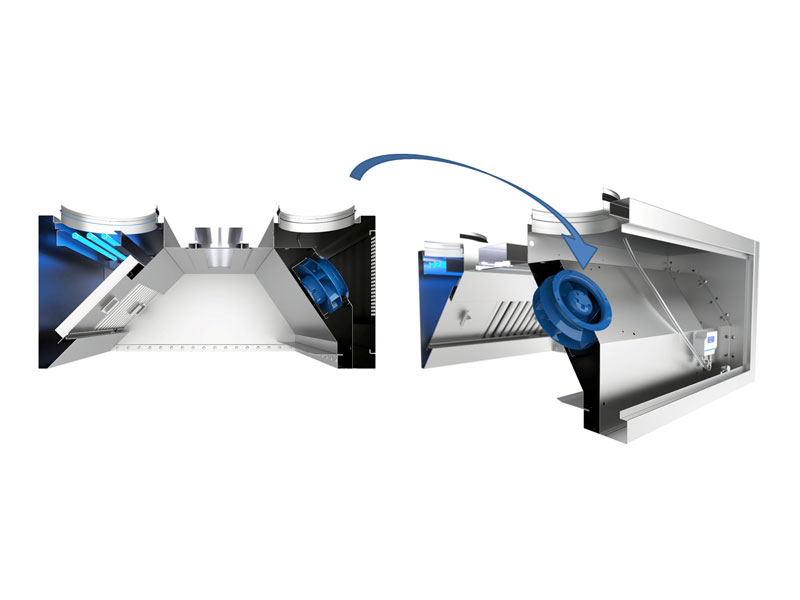

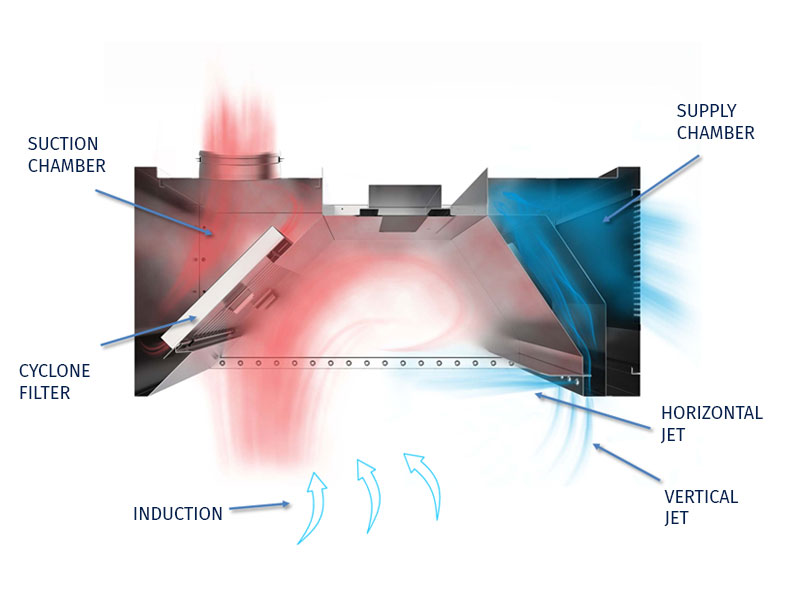

- Two sets of patented and uniquely shaped nozzles that serve to create an induction horizontal air jet and a vertical air curtain.

- Built-in EC fan that maintains the pressure in the supply unit via a pressure sensor ensuring an even induction air jet along the hood edge.

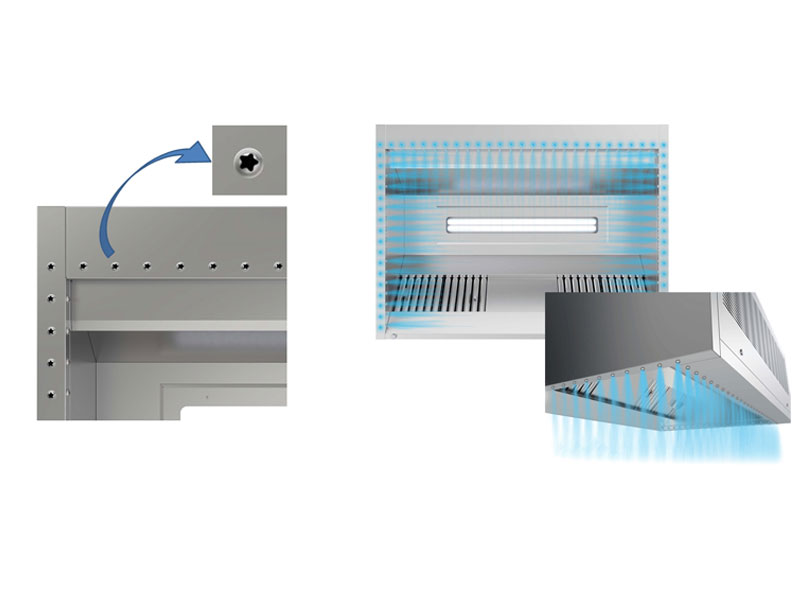

- Possibility of supplying fresh air to the space via an aesthetically perforated diffuser on the front panel, designed in such a way that it does not change the dimensions of the kitchen hood.

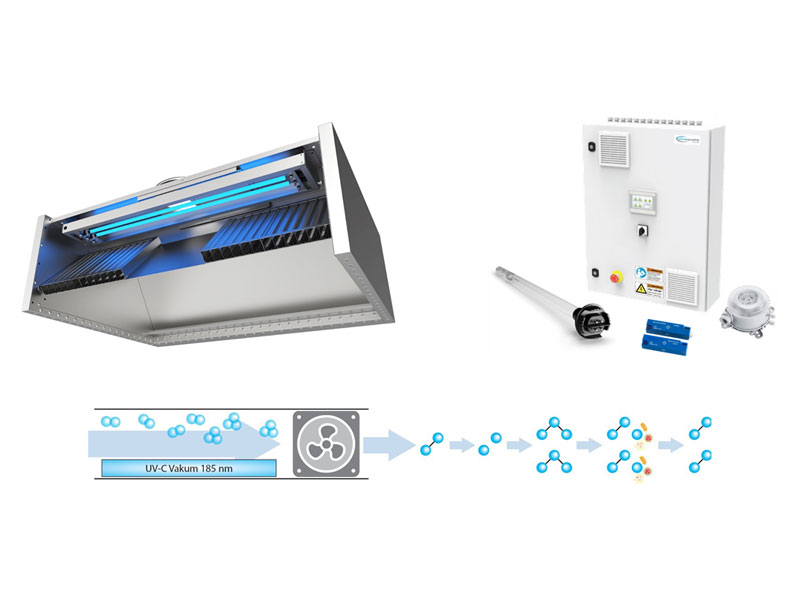

- Compatibility of the kitchen hood with the UV Ozone System for disinfection and unpleasant odors removal.

- The high efficiency of the induction kitchen hood in aerosol extraction is achieved by a constant horizontal induction air jet that creates a negative pressure in the space between the hood and the hot surfaces, causing the steam from cooking to rise and be directed to the kitchen hood filters. The spread of smoke and steam into the space is prevented by the vertical air jet created by the nozzles on the underside of the hood edge.

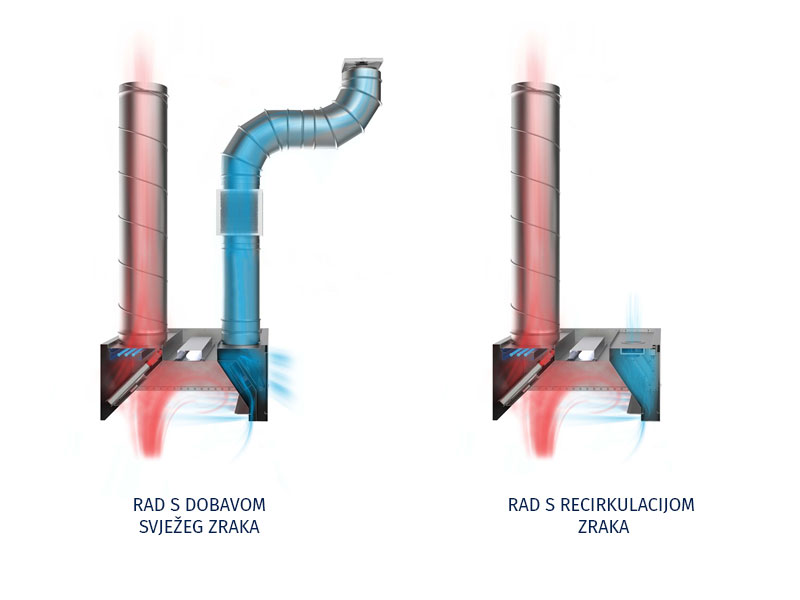

- Additionally, induction kitchen hoods have the option of operating with fresh, filtered, and preheated air, or recirculated air from the room, depending on how the hood supply connection is connected.

Additional advantages in new line of kitchen hoods design

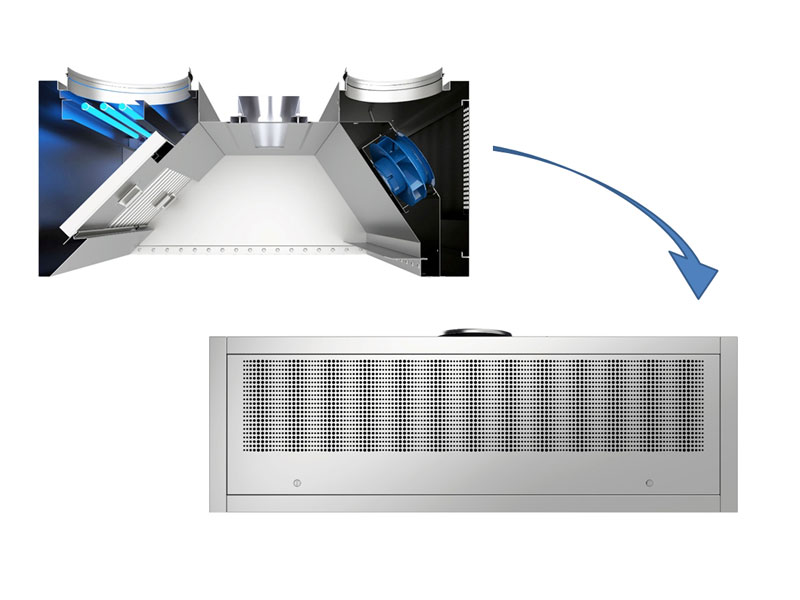

Along with the mentioned advantages in the design and operation of induction kitchen hoods, there are additional design solutions on this, completely new, line of hoods that increase efficiency, ensure safety and are easy to use. These are primarily new models of cyclonic filters, but also integrated regulating dampers, LED lighting, a new stainless steel suspension system and valves for draining condensate and grease.The operation of cyclonic filters is based on the principle of centrifugal force, removing grease particles with an efficiency of up to 95%. When the air, full of grease particles and impurities, enters the cyclonic filter, a rotating current is created in which grease particles, due to inertia, hit the inner walls of the filter channel where they build up, while the cyclone stream of filtered air is expelled from the filter.

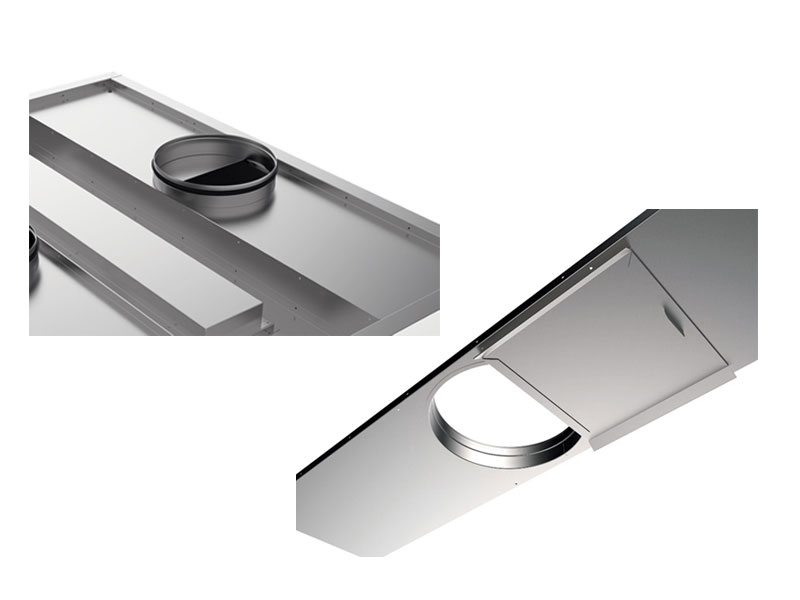

Regulating sliding dampers are integrated on all exhaust and supply connections, making it is possible to easily balance exhaust and air supply. The dampers are installed in such a way that they do not increase the dimensions of the kitchen hood.

LED lighting is built into the top panel of the hood in a way that allows easy cleaning and maintenance. The color of the LED lighting is 4000K, it is very pleasing to the eyes and illuminates the workspace very well.

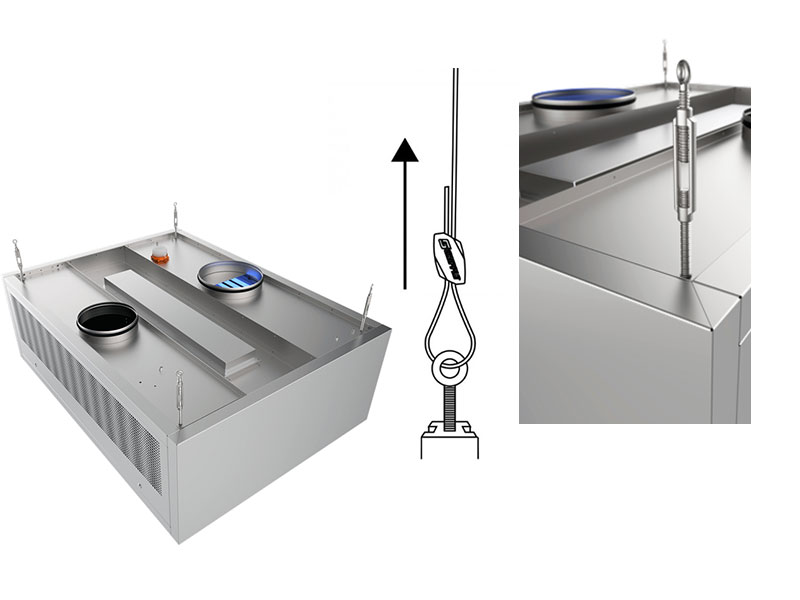

The hood comes with a set for easy hanging and leveling of the kitchen hood without the use of tools, which consists of a clamp, a steel rope, and a mechanism for adjusting the height.

The condensate on the hood is drained by opening the plug on the stainless steel valve. The valve is located at the lowest position of the hood to ensure proper collection and drainage of moisture and liquefied grease.